Blow up a balloon and then release it. It flies around the room.

What you’ve just demonstrated could give us a stable electric grid, cut emissions at data centers, and avoid tons of greenhouse gas entering the atmosphere.

You see, we want to decarbonize the electric grid, by switching off coal plants and replacing them with renewable sources like solar and wind. UN Secretary-General António Guterres says there must be no more coal power plants built after this year.

But there’s a big problem. One that is easy to state - but really, really hard to solve.

This article appeared in our Grid Scale Supplement. Read the whole thing here

Renewables don’t work all the time. Fossil fuels do.

Solar and wind power only flow when the sun shines and the wind blows. But our demand for electricity continues regardless, so we have to have power sources, like coal and gas-fired fossil fuel generation, which can be switched on as needed.

To wean ourselves off fossil generation, we need ways to store energy created at the peaks of renewable production, so it’s available on a cold, dark night.

We can’t all do pumped hydro

We’re already using big energy storage systems, like pumped hydroelectric storage, based on hydroelectric stations fed from large lakes in mountains. Run the power station in reverse, and it pumps water up to the lake, storing energy. The UK’s Dynorwig station in Wales can store up to 9GWh of energy. and deliver it at a rate of up to 1.8GW.

But you can’t build a Dynorwig anywhere. So other options are being proposed, ranging from high-tech new battery technologies, through using electrolysis to create green hydrogen, to the really low-tech option of cranes that simply lift giant concrete blocks into the air to store potential energy.

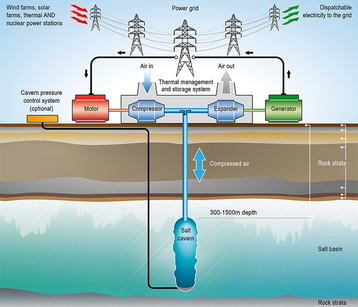

Compressed air is also on that list. Blow up a balloon and you compress air inside it, storing energy. Allow it to expand, and the energy is released. Physicists explain this with Boyle’s Law.

The idea has been used to run trains in mines without a risk of explosions, and more recently has been scaled up to utility levels.

“Storelectric’s CAES plants are usually designed as stand-alone plants with stand-alone profits based on buying electricity from the grid and selling it back to the grid,” says Mark Howitt, CTO at Storelectric, a company which aims to offer CAES as an energy storage service for utility grids.

Howitt says CAES is ideal for data centers, as they can fund the storage system through power purchase agreements, and benefit from a steady clean energy supply.

“Storelectric’s fully validated simplifications of existing, well-proven technologies offer 30-60 percent IRR (internal rate of return) stand-alone and 50-70 percent in conjunction with renewables, which also reduces the capital costs and improves the profitability of the renewables,” he says.

The company has plans for two CAES plants storing 200MWh and 2.5GWh of energy in underground salt caverns, and an engineering company ready to build the plant, but those plans are on hold right now, as the company looks for funding.

Brexit has made it harder for Storelectric to raise money and trade on the continent of Europe but Howitt believes it may have the side-effect of increasing the need for energy storage, because in times of grid stress, European nations rely on interconnectors to provide power where there is a shortage.

These connectors will still exist, but they will be available on different terms after Brexit, Howitt warned DCD: “While we were in the European Union, legally the UK had to be treated as a domestic customer. Now we are no longer legally treated as a domestic customer - we're an export destination, and would be less favored than domestic users.”

So more energy storage will be needed, he believes. On this and other issues, Howitt runs a very informative blog.

CAES’ proven history

CAES is well proven, having been in use since 1978 at a 300MW plant at Huntorf, Germany belonging to EN Kraftwerke. Meanwhile, Alabama Electric Corp has run a 110MW plant in McIntosh since 1991.

Like Storelectric, those plants pump air into underground salt caverns, but these early systems use the energy to assist a gas turbine, which doesn’t eliminate the use of fossil fuels, and aren’t particularly efficient, operating at around 40 to 50 percent.

The next generations of CAES are working to improve on that - and the problem they face is that compressing air makes it hotter. If that heat is lost, efficiency is reduced.

“All compressed air storage systems try to separate the air from its thermal energy and store those two separately, such that they may then be recombined later,” says Liam Newcombe, senior vice president of engineering at Energy Internet Corporation (EIC), a startup proposing giant CAES systems storing air in spent oil wells.

Essentially, when a gas is compressed it generates heat. When it expands it needs to take in heat. If you saved the heat when you compress the gas, you can use it in the expansion process.

Because CAES can hold energy for a long time, it’s got potential for large-scale smoothing of the grid, says Newcombe: “You can have very long durations of storage using compressed air in subsurface geological features. You don’t use that to move the California solar peak four hours later, every single day, to hit the demand peak for air conditioning. You use it for periodic deep storage interventions on the grid, that get you from an 80 or 90 percent renewable grid to 100 percent renewable.”

CAES systems should be “the ones that you call when the batteries the on solar farms have all hit zero and it's still cloudy, and it's still cold and there's no wind,” he explains. “They’re the times the UK calls on Drax [a coal/biomass generator plant in Yorkshire] to start up the turbines, and we call on all the gas capacity - which we do a couple times a year, for a week or so at a time.”

They are far more scalable than batteries, which can charge and discharge cheaply, but have a high cost per unit of energy stored, he explains “If you want to store twice as much energy, you buy twice as many batteries. With compressed air, if you're pushing it into a subsurface feature, the incremental cost of an extra million liters of compressed air is very little, because geological features are just bloody big to start with.”

Liquid air

Highview Power takes a different approach: it compresses the air much further, until it condenses into a liquid. Its pilot plants in the UK and the US, which include a 50MW-scale plant near Manchester, use small-scale above-ground equipment which could suit data center needs.

Liquid air systems don’t need underground reservoirs and can store energy for a long time. The downside is they generate much more heat (on condensation) and cold (on evaporation) - so the process means a large heat store or else losing a lot of energy.

But it could be good for digital operators, a spokesperson told DCD: “At very large-scale Highview Power’s cryogenic energy storage technology can help data center operations. Highview has grid-connected systems that can store power from air for hours to even days.”

Highview’s latest announcement is a 50MW plant being constructed in the Atacama desert in Chile, in partnership with local utility Energía Latina S.A.-Enlasa. It’s a good fit, as the location can readily produce a large surplus of solar power.

Data center partners

Among CAES companies, the one that talks most vocally about partnering with data centers is the US-based Energy Internet Corporation (EIC) - perhaps because its CEO Shankar Ramamurthy knows the territory, having previously run VPS, a startup which aimed to get flexible power provision into data center racks.

EIC has a system that uses a “liquid piston,” and is simultaneously working on big projects below ground, along with smaller ones above ground, which will use a liquid air system similar to Highview’s.

”We will have products ranging from one megawatt based on liquid air, potentially scaling up to a gigawatt or more,” Ramamurthy told DCD. The company is using engineering partners. like process firm Lummus, to deliver its designs.

EIC plans to show pilot schemes for compressed and liquid air next year, Ramamurthy says. One EIC project is a 5MW zero carbon microgrid, being developed with a utility company and a California oil and gas firm.

According to Ramamurthy, the 5MW project will “demonstrate a full operating system, with subsurface storage and the microgrid distribution, as well as a green interface.”

He says this project can be scaled up to a 2GW plant, with 30 to 50 days of energy storage: “Which by the way is TeraWatt hour (TWh) scale, supporting a genuinely zero-carbon power strategy.”

More pertinently to data centers, EIC is also working on a 1MW liquid air project designed specifically to feed steady green power to data centers. Ramamurthy says this project is with a “large chip company.” Since the company has previously announced exploratory work with Intel, it seems likely Intel is the partner here.

And finally, in Bahrain, there’s a 600kW solution designed to offer steady zero-carbon power. That should be up and running by summer of 2022, he says.

“We expect commercial products to be available towards the end of next year, at all scales,” he says, and the smaller systems will definitely be offered to data centers as off-grid power storage.

Recycling old oil wells

For its larger infrastructure projects, EIC uses depleted oil and gas wells to store the compressed air. The company hopes that oil companies will want to repeat the 5MW test.

“We are talking to one of the largest oil and gas companies in California,” says Ramamurthy. “They have over 5,000 depleted wells and a number of reservoirs in central California. We have identified a number of candidate reservoirs.”

Oil firms will jump at the chance of recycling old wells, and Ramamurthy believes they will be persuaded into a more active green strategy by the prospect of giving new life to oil well sites.

"Subsurface reservoirs like depleted oil and gas reservoirs are the best assets. They already have all the pipelines in place, and there is decades of analysis data at a very, very granular level to understand precisely how that reservoir will work” he told DCD. “Oil and gas companies can really start leveraging their assets to beautifully get into clean energy.”

Many oil wells are coming to the end of their life, he says: “Oil and gas companies will have to spend billions of dollars in decommissioning. So instead of spending that to make them dead assets. How about actually repurposing them, to provide clean energy? That way, an oil and gas company has created a clean energy future where they can sell a much more value-added product.

“This gives a segue for oil and gas companies to recognize an alternate richer future,” he says. “Instead of passively resisting the change, this would encourage them to accelerate and become the movers and shakers in this transition, and the whole of society would benefit.”

Taking in other underground features as well, suitable reservoirs are accessible from 80 percent of the US today, he says, and he echoes Newcombe’s comment on scalability: “For other systems, if you want to store more energy, you're going to have to spend more. In our case, you are actually going to have to spend less.”

The liquid piston

Within its systems, EIC attempts to keep the expansion as adiabatic as possible - minimal heat transfers in and out of the system, using water sprays within its compression cylinders to maintain a steady temperature (isothermal compression).

It also operates a series of compression cylinders at increasing pressures to avoid a large compression stage.

The “liquid piston” the company describes, simply means the expansion happens in a vertical cylinder pushing down on a head of water, rather than hydraulically driving a mechanical piston.

“The liquid piston is our invention - and it’s one of the elements that enables this to work with really large underground reservoirs,” says Ramamurthy, adding that moving a body of water “make this less compressed air and more pumped hydro.

“Anyone who doesn't see the rest of the system, and looks at our hydroelectric plant, will go away with the impression that is pumped hydro,” he says.

So it benefits from techniques used in plants like the UK’s Dynorwig, without needing to find a mountain with a high lake because, instead of pumping water up to a lake, it’s pumping water into a compression stage that drives the compressed air underground.

“So this is really a pumped hydro system,” he says. “It's a pumped hydro system on steroids.”

EIC uses existing off-the-shelf equipment, which is a benefit, but also a limitation, in that it adds the requirement for multiple compression stages, says Ramamurthy. Much of this will improve in future versions.

“We have the potential to be the lowest-cost energy,” he says. “That's our mission, to make our energy less expensive than what is available on the fossil fuel grid today.”

It’s an urgent task, because “we don't really have the 30 or 40 years that governments are planning for a leisurely transition. The climate may be a lot more unforgiving than the delusionary times that we are allowing for our transition.”